Light, strong, and tough: Researchers discover unique polymer fibres

"The fibres we discovered can be produced easily using high-tech processes that are already established in the industry - and on the basis of polymers that are readily available worldwide. One individual fibre is as thin as a human hair, weighs less than a fruit fly, and yet is very strong: It can lift a weight of 30 grams without tearing. This corresponds to about 150,000 times the weight of a fruit fly. Experiments on the high tensile strength of these fibres have furthermore revealed their extraordinary robustness. This means that each individual fibre can absorb a lot of energy," explains Prof. Dr. Andreas Greiner, who is the head of the research group Macromolecular Chemistry II at the University of Bayreuth, and who guided the research work. Also involved were researchers at the Forschungszentrum Jülich, the Martin Luther University Halle-Wittenberg, the Fraunhofer-Institute for Microstructure of Materials and Systems (IMWS), the Rheinisch-Westfälische Technische Hochschule Aachen University, the Jiangxi Normal University, Nanchang, and the ETH Zürich.

Due to their extraordinary properties, the polymer fibres are ideally suited for technical components that are exposed to high loads. They enable innovative applications in a wide variety of fields, for example in the textile industry or medical technology, in automotive engineering, or in the aerospace industry. In addition, the polymer fibres can be recycled well. "We are certain that our research results have opened the door to a new, forward-looking class of materials. Practical applications on the part of industry can be expected in the near future. In polymer science, our fibres will be able to provide valuable services in the further research and development of high-performance functional materials," says Greiner.

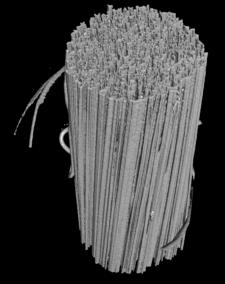

The chemical basis of these promising fibres is polyacrylonitrile. A single fibre with a diameter of about 40,000 nanometres consists of up to 4,000 ultra-thin fibrils. These fibrils are linked by small amounts of an additive. "Their unique strength in combination with high toughness never ceased to fascinate us," says the Bayreuth polymer scientist Prof. Dr. Seema Agarwal.

Three-dimensional X-ray images produced at MLU show that the fibrils within the fibre are almost always arranged in the same longitudinal direction. Calculations made at MLU based on the microscopy data also revealed a mostly straight arrangement. "Only with high-resolution 3D X-ray imaging we could see the arrangement of all fibrils within one single fibre in detail," says Dr Juliana Martins de Souza e Silva, leader of the X-ray imaging group at MLU and habilitation candidate of Professor Ralf Wehrspohn, who is head of the Chair for Microstructural Material Design at the Institute of Physics and Executive Vice President for Technology Marketing and Business Models at Fraunhofer-Gesellschaft. "The device we have here is quite special," says Martins. "Normal X-ray microscopes are unable to easily detect carbon-based materials like the polyacrylonitrile fibres. For this you need special technology." The Zeiss Xradia 810 Ultra does have this technology - X-ray phase-contrast imaging. In Germany there are only very few of these microscopes available for use in research.

About the study: Liao et al. High strength in combination with high toughness in robust and sustainable polymeric materials. Science (2019), doi: 10.1126/science.aay9033